Specialized Cell

Manufacturing Center

Providing multi-category, multi-model, multi-batch, high-quality special customization.

*Multi-category

In terms of material systems, we currently have mature products in multiple systems such as ternary, lithium cobalt oxide, lithium iron phosphate, and composite. In terms of performance, our product categories include low-temperature charge-discharge batteries, low-temperature high-rate batteries, special batteries with both high and low-temperature performance, high safety batteries with certain explosion-proof and coal mining safety features, and low-temperature high-energy density batteries.

*Multi-model

In terms of physical structure, our products cover cylindrical 18650, cylindrical 26650, square aluminum shell 2270160, and various sizes of pouch cells. In terms of process design, product models include high-rate stacked electrode process models and conventional winding process models.

*Multi-batch

We can undertake battery orders of various quantities, ranging from small batches of 600Ah to large batches of 50,000Ah and above, covering a wide range of batch sizes.

*High-quality special customization

Products can be developed, designed, and validated according to the unique performance requirements of customers, achieving special customization. The high quality is mainly reflected in:

Whether it is sample development or production, we have strict quality control procedures and measures. From electrode sheets to finished batteries, there are data records and full inspection processes, allowing for traceability of battery capacity, self-discharge data, and more.

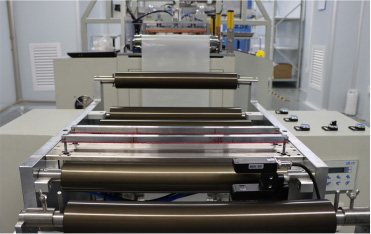

The Specialized Cell Manufacturing Center possesses

Specialized cylindrical production line

Specialized polymer winding production line

Specialized stacked electrode production line

Specialized Battery

Manufacturing Center

Offering a wide range of varieties and batches, with quick response, we provide high-quality customized PACK solutions that fully meet the personalized and diverse needs of customers.

*Multiple Varieties

The products are widely applicable in industries and fields such as medical, special applications, marine, surveying and mapping, security and surveillance, electric tools, and more. The manufacturing processes, performance, dimensions, and assembly methods of the products are diversified to meet the diverse needs of industry customers.

*Multiple Batches

The manufacturing center handles sample orders, small volume orders, batch production orders, and large volume production orders. Based on the urgency of customer requirements, a rolling planning mode is adopted, and deliveries are made in batches to meet customer demands. The manufacturing production modes are diverse, including lean unit production, assembly line production, pull production, one-piece flow production, rapid tooling change, and other lean production modes. The production is carried out in a combination of assembly stations and assembly lines, ensuring seamless switching and on-time delivery between different types of products

*Quick Response

The workforce is versatile, with rolling production plans, unit grouping operations, rapid tooling change, and flexible adjustments between production lines. All staff members are always on standby to ensure quality and quantity, making customer satisfaction the top priority.

*High-Quality Customization

The entire process is traceable with a full traceability system in place. Automated or semi-automated operations are employed, with key positions assigned to specific individuals for accountability and traceability. Each production process undergoes self-inspection, mutual inspection, and specialized inspection. Comprehensive inspections are conducted before shipment, with dedicated personnel conducting quality sampling inspections. Key components are tested using high-precision testing equipment or specialized devices. The production site follows standardized management practices, with on-site guidance and inspections by professional technicians and quality assurance personnel. The production environment is intelligently monitored, and production and testing equipment undergo regular calibration. The principle of “no unclear causes, no unidentified responsibilities, no lack of corrective measures” is strictly followed, and all team members make unremitting efforts to establish a production level that is super safe, super reliable, and of high quality.

*Senior Customization

Specializing in customized production of special lithium battery modules.

*Agile Customization

Flexible manufacturing system.

*High-Quality Customization

Zero-voltage cell matching system, full traceability system.